Growing crops in a greenhouse can be not only useful, but also able to bring aesthetic pleasure. It is one thing when the room is assembled from improvised materials (boards, sticks, film), another thing when a well-thought-out structure made of aluminum frame and glass flaunts on a personal plot. How to create such a building is discussed in this article.

Features of greenhouses made of aluminum and glass

With all the high cost, such structures fit perfectly into the design of the site, decorating it. Although they are not capital buildings, they are quite durable. They can carry out communications without fear that a gust of wind will blow away an unreliable structure. To create a greenhouse made of aluminum with glazing, you will need to put a lot of effort and spend time. However, the finished structure will last a long time and will be strong.

Advantages and disadvantages

- The construction of this type of greenhouses has its undeniable advantages:

- small mass of load-bearing structures;

- resistance to the action of the environment - do not rot, do not oxidize, do not rust;

- practicality - no need to paint or treat with pest and fire fighting agents;

- durability - materials can serve for many years;

- strength - aluminum is a very durable material;

- ease of operation - ease of processing (cutting, bending, forging) of aluminum makes it an excellent structural metal;

- aesthetics - a skillfully constructed greenhouse looks beautiful and organic.

Important! All the disadvantages are easy to fix - the foundation will decorate the building and give it solidity, broken windows are replaced with new ones, and in the heat the room is ventilated or ventilated.

- The disadvantages of this type of buildings are also available:

- with the ease of supporting structures, the mass of glazing forces to prepare the foundation for the building;

- glass, unlike polycarbonate, poorly resists to a hail or hurricane wind;

- high temperature indoors on hot days.

How to build a greenhouse made of aluminum under glass

For self-construction, not only financial resources are needed, but also the proper planning of the site, the preparation of project drawings, tools, materials and, of course, a great desire to complete the plan.

Preparation for construction

After choosing the site on which the construction will be built, it is necessary to conduct high-quality preparation - the work should be carried out as soon as possible so that the new greenhouse starts operation as soon as possible. To do this, you need knowledge that can be gleaned from resources on the Internet or in consultation with experienced specialists.

What materials will be needed

For the simplest strip foundation, you will need: cement, sand and water. The quantity is determined based on the project, - the dimensions of the greenhouse can be different, as well as the dimensions of the foundation under it.

Important! A U-shaped aluminum profile can have a narrow groove for installing one glass or wide for a double-glazed window. When buying, you need to pay attention to this nuance.

For structures and their assembly such materials are needed:

- square aluminum tube - 20 × 20 mm with a wall thickness of 1.5 mm;

- aluminum U-shaped profile 20 × 20 × 20 mm with grooves for placing glazing in them;

- sheet glass - a thickness of 3-4 mm;

- universal external sealant - for fixing glass;

- hardware products of the selected size and thread;

- rubber profile - U-shaped and E-shaped.

Necessary tools

Preparation of the mix for the foundation will require a portable concrete mixer or a traditional trough with a shovel. It’s good to have a wheelbarrow at your disposal to transport the finished solution to the pouring place, so as not to drag it with buckets.

An approximate list of tools for assembling and installing structures is as follows:

- a puncher or drill with a set of drills for working on different materials;

- screwdriver;

- Bulgarian;

- a set of tools - pliers, wire cutters, a hammer, a glass cutter, a hacksaw for metal, wrenches, a set of several screwdrivers, etc .;

- vacuum suction cups for hands.

Did you know? Greenhouses in Iceland are built in close proximity to geysers using the heat of a natural source. Tourists in this country know that if you see a greenhouse, then there is a geyser nearby.

Dimensions and drawing

Even at the stage of choosing a construction site, it is necessary to imagine what structure will be located here. Therefore, it is not necessary to neglect the design stage. The dimensions of the future greenhouse should be organically fit into the infield. No need to build a structure from the fence to the fence.

Aluminum Greenhouse Drawing

Aluminum Greenhouse Drawing

For construction, you need at least the simplest drawing with dimensions. In the absence of special complaints, it is worth using the scheme of a conventional gable greenhouse taken from the Internet. In it, you just need to change the sizes to your own and recount the materials. If possible, then many design organizations will help create a building of any level of pretentiousness.

Step-by-step construction of the greenhouse

After preparing the foundation of cement or wooden blocks, work begins on the assembly of the entire structure. In this case, it is necessary to carefully adhere to the drawing and photo, as well as carefully prepare structural elements.

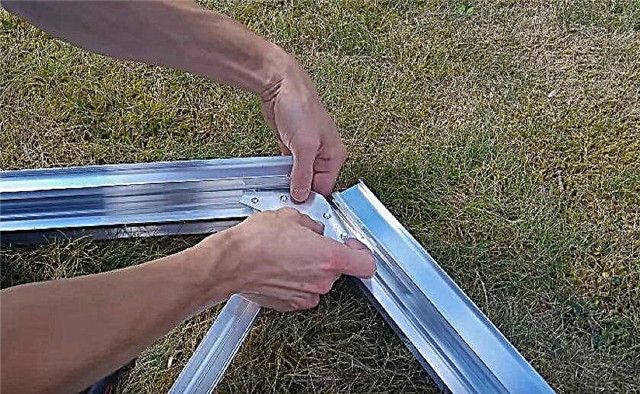

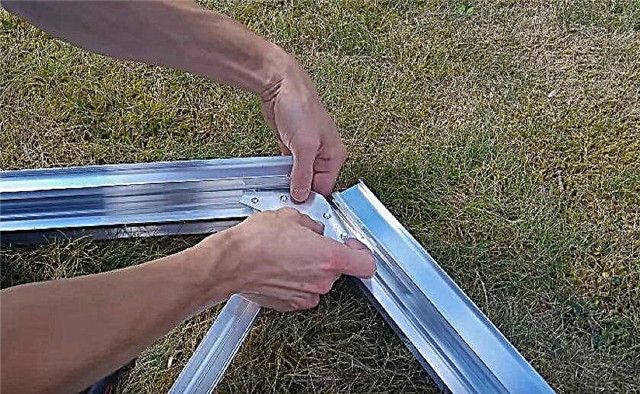

Frame assembly

With self-assembly of the frame, three methods of connecting structures are possible:

- bolted - involves the subsequent dismantling of the building, if the need arises;

- with rivets - The most convenient and fast assembly, but one-piece;

- welded - time-consuming, special equipment and experience are also needed, also one-piece.

Also pay attention to other features of the installation of greenhouses and their varieties:

The easiest way to deal with a ready-made kit for building a greenhouse - these are sold in specialized stores. There is no need to solve complex problems, but just follow the attached instructions. In this case, it is better to choose models with bolted connections. They are a little more expensive than those that are assembled on latches in the grooves, but more reliable and durable.

The assembly diagram of the frame from the factory profile is as follows:

- Unpack and check for completeness according to the list.

- Lay out in the correct order the details of one of the ends of the building on the ground.

- Attach all struts and jibs (if any) to the beam of the base of the frame.

- Also attach all the racks to the top of the end.

- Rafters are connected with a special common plate with holes for racks.

- The opposite end of the future greenhouse is mounted in the same way.

- The ends are installed on the base, foundation or wooden beams using foundation bolts.

- Lay out the details for one of the walls of the structure on the ground.

- From left to right (or from right to left) mount the struts and jibs to the lower beam.

- Also assemble another wall.

- Install both walls on the base and connect them to the ends.

- Attach the skate to the ends, and the intermediate rafters to it.

- Install cross ties on the rafters.

Roof installation

The roof is first installed on the finished frame. This is not the most convenient event, so you need to prepare for it - clear the place for installation, bring coasters or stepladders.

Glasses are mounted in this way:

- Glue the lower and upper edge of the sheet with a U-shaped rubber profile.

- Using a vacuum suction cup, insert it into the grooves of the rafters.

- Outside glue with an E-shaped profile or rubber tape.

- Repeat the previous steps for the remaining roof panes.

Did you know? In Scandinavia, greenhouses are often an extension to a residential building. This is convenient for moving there without moving along the street, and the communications of the house are easy to extend into the adjacent room.

Wall construction

After the roof is built, you can proceed to glazing the side walls.

This is done in the following sequence:

- In the extreme right or left section of the wall, the grooves of the racks are glued with a U-shaped profile.

- A sheet of glass is inserted into this rubber profile.

- Glass is fixed outside with a rubber band.

- Repeat the previous steps for the remaining sections of the wall and glaze another wall in the same way.

After the walls you need to glaze and the ends of the greenhouse. Here, the work is carried out in the same sequence, but you need to be especially careful when installing oblique glass. The independent construction of the greenhouse is a creative process.

It can be mastered only by experienced craftsmen who are capable of themselves and almost "by eye" to determine the necessary dimensions of the cut or welding. However, the general recommendations given above can be taken as a basis for the construction of greenhouses of any size and configuration.

Useful Tips

The cost of materials for creating any kind of greenhouses "bites", so everyone chooses according to their capabilities. It is worth noting that, for all its durability and functionality, the aluminum profile and glass require several great efforts to create a structure out of them.

Experienced greenhouses recommend not abandoning the wooden foundation in favor of time-consuming concrete. It is enough to pour sand or screenings in the trench under the log, and put bricks in the corners - this design will last 10 years or more. When planning heating, lighting and irrigation systems, the room is still better to do on a good foundation.

In an unused period (if there is one), it is better to remove the glass - this will save them from snow mass and seasonal heavy winds. If the glass is still broken, but there is no replacement at hand, you can put a sheet of polycarbonate or reinforced film in the frame.

The greenhouse in the garden will become a source of vegetables and herbs even in the harshest time of the year. Here you can grow not only seedlings, but also full-fledged crops from seed to fruiting. It is only necessary to approach the issue of arrangement previously prepared technically and theoretically.