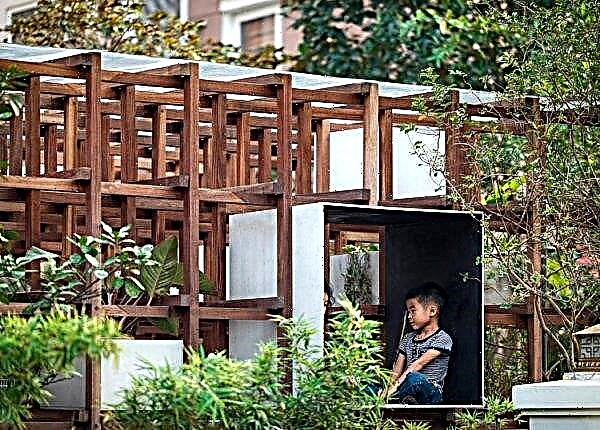

A rare recreation area on a country site without a cozy gazebo. Despite the spread of modern design styles, traditional antique wooden buildings do not lose their popularity. An additional plus is that you can build a gazebo from a tree yourself. The following describes the design features, the selection of suitable materials and tools, as well as recommendations for caring for the finished structure.

Options and ideas for an old-style gazebo

The wooden arbor in the old style allows you to realize such design principles as naturalness and environmental friendliness.

Did you know? A light gazebo on a hill, from where you can observe the surroundings, is called a belvedere, which is translated from Italian as “beautiful view”.

The appearance of such buildings is distinguished by reliability and solidity, and the main characteristic features of the structure are:

- open log cabin with a perimeter fence and a massive roof;

- carved decoration of various elements (poles, guard railing, roof skates, etc.);

- wooden furniture with the effect of aging.

An ancient arbor can be either round or rectangular, often there are construction projects with a polygonal base. A small staircase of 2-3 steps with carved railings will give the building lightness and grace. If there is free space, the arbor can be equipped with a traditional stove and a large table, benches are often mounted on walls.

An ancient arbor can be either round or rectangular, often there are construction projects with a polygonal base. A small staircase of 2-3 steps with carved railings will give the building lightness and grace. If there is free space, the arbor can be equipped with a traditional stove and a large table, benches are often mounted on walls.

The decor in the old style often includes the use of traditional paintings, textile accessories with embroidery and lace. In this case, it is important to maintain a balance between decoration and structural elements, so as not to overload the design.

Did you know? Eucalyptus wood materials are not only durable and beautiful, but also have a pleasant smell. Eucalyptus essential oil has recognized antiseptic properties and is used to prevent various diseases.

The choice of building materials

When choosing material for construction, one should take into account the advantages and disadvantages characteristic of each tree species. Experienced craftsmen recommend using oak, cedar, larch or beech, and if the construction budget is limited, pine or linden.

The following types of wood suitable for self-assembly are on sale:

- timber, which can be made of solid wood, be glued or profiled. The last two options are characterized by high strength and low percentage of shrinkage, they do not warp and do not rot. If it is planned to build a gazebo of a closed type, an important plus will be a high rate of thermal preservation of such material;

- the block house is a semicircular sawn timber and in finished form gives the arbor the effect of a log house. Commonly used as carcass cladding;

- The grooved board has the characteristics of a block house, but has a flat surface. Attached to the frame through a system of grooves and spikes on the side surfaces;

- carved board is used for decorative decoration. If desired, the pattern can be cut independently or ordered from the master on an individual project;

- plain board, which must undergo special treatment with antiseptics;

- wooden logs after simple bark removal - inexpensive material, but its processing will require additional time and effort. At a higher price, you can buy calibrated logs with the same diameter along the entire length.

Before work, the tree must be subjected to special treatment to protect it from moisture, burning, decay and pests. Usually they use impregnation with antiseptic compounds and flame retardants (to impart incombustibility properties), then a primer and coating with paint, varnish or wax are performed. The material of the roof is selected taking into account its shape and the selected foundation. For an old-fashioned gazebo, soft tiles will be most suitable.

How to make artificial aging of a tree

To use the materials that match the old style of the gazebo, you can apply artificial aging of wooden elements. The result is a material with an individual surface that emphasizes the design of the building. Moreover, this treatment additionally increases the strength and durability of the tree, since paints and varnishes with protective properties are used in the work. Most often, exposed beams and floor, furniture surface (table, benches, etc.).

You can apply one of three techniques:

- firing, in which exposure to heat changes the color and pattern of the wood surface. Firing is performed with special burners and lamps (gas, blowtorches);

- brushing, in which a mechanical tool (usually with a brush) performs relief adjustment;

- processing with special chemicals (alkalis and acids), which unevenly destroy the structure of the tree, forming a new relief.

Important! Pine, oak, walnut, ash and larch are suitable for aging, but this technique is not used for fruit species, beech, teak, teak, alder and maple.

After obtaining the desired surface, the tree is treated with protective impregnation, paint or stain, varnish. The above methods physically change the structure of the tree. There is also a patching technique that only creates the illusion of a new surface using special paints, stains and waxes.

Video: do-it-yourself artificial aging of wood

Layout and preparation of a drawing with dimensions

Before calculating the design, determine its exact size, which will depend both on the area of the site, and on the purpose of the gazebo, the composition of the family, etc. It is also recommended to take into account the standard sizes of building materials, which will allow using it with maximum savings and without additional trimming.

Important! When planning, it is necessary to take into account the norms of SNiP, observing the indicated distance of remoteness from the house and the borders with neighboring areas.

The most common sizes of arbors:

- 3 × 3 m. The compact square gazebo is designed for a comfortable stay of 6 people (maximum - 10);

- 3 × 4 m. Such a structure can accommodate up to 12 people, a rectangular shape is easy to install;

- 4 × 4 m. Classic spacious gazebo for 8-10 people (maximum - 15);

- 4 × 5 m. This construction allows you to install the stove inside and will comfortably accommodate 15 people.

In a small area, a gazebo of 2–2.2 m in size can be installed. With such an area, it is no longer possible to freely arrange the chairs, so a bench is placed around the perimeter. Having developed the design and specifying the size of the gazebo, you should prepare drawings and think through all the connecting elements. Typically, a construction drawing is made in two projections (frontal and profile), indicating all technical nodes. If possible, it is advisable to provide wiring for connecting lighting. An accurate plan will allow you to calculate the required amount of materials for the purchase.

Necessary materials and tools

The list of materials and tools for each project is individual, but common points for most buildings can be distinguished.

For marking, cutting and installation you will need:

- building cord, tape measure and water level, square, pencil or marker;

- grinder, jigsaw and plane, sandpaper or grinder;

- hammer and screwdriver, wrenches;

- stepladder, shovel, construction drill.

The list of building materials should include:

- everything for the construction of the foundation (for example, crushed stone, sand, cement);

- materials for the frame, floor and lining of the gazebo;

- roof elements;

- a sufficient amount of fasteners (nails, screws, etc.);

- paints, protective impregnations, varnish.

The process of building an antique gazebo made of wood

Construction of the gazebo begins with the placement of the building on the site and marking the territory. The selected area should be cleaned and leveled, removing about 10 cm of the soil layer.

Further work is performed in the following sequence:

- Foundation laying. Since a wooden structure will have less weight than a brick or stone building, a pile or column foundation is planned for it. For buildings of large size, including a furnace, as well as in swampy areas or with a high level of groundwater, a monolithic foundation in the form of a slab is performed.

- Base and bottom harness. For the base, square blocks of 10 × 10 cm are suitable. One such beam is installed in the center, the other in the corners. They are fixed to the fittings, and then connected to each other for a strong and reliable design. Provide ventilation under the floor, leaving a distance between the bars and the ground. Floor laying is carried out taking into account the operational characteristics of the material, which can often change its physical parameters under the influence of humidity and temperature, so installation is usually performed with small gaps (about 2 mm), which also provides drainage in case of heavy rainfall.

- Frame and upper harness. Smooth bars about 2–2.5 m long are used for the arbor frame. They are fixed with metal corners, after which the arbor is trimmed with selected materials according to the developed design.

- Installation of the roof. The rafter system is made of both flat boards and square ones. It is fixed using the “half-tree” technology, for which special cuts are used, which should coincide on the parts to be joined. For a small-sized gazebo, the roof frame can be assembled on the ground, and then lift and fasten it ready-made. For structural strength, a small support beam with a cross section of 9 × 9 cm is mounted in the center, to which the first two frame rails are attached. After fixing on the supporting posts, the roof is covered with the selected material.

How to care for a wooden gazebo

Wooden arbor will require special care from the owner, especially in preparation for winter. In autumn, the building should be cleaned of fallen leaves, otherwise its accumulation can lead to darkening and decay of the wood. For additional protection, open and half-open structures can be closed with a film, awning or other dense material, leaving openings for air exchange. In winter, snow accumulations should be removed from the roof to prevent its collapse from a heavy load.

Pre-construction processing of materials has no lifelong action. To update the protective properties of surfaces, it is necessary to remove dust and dirt from structural elements. If mold spots are found, they should be treated with special preparations according to the instructions. The metal parts of the fasteners are covered with corrosion solutions, and the wooden parts are coated with antiseptics.

The old-fashioned wooden gazebo will provide outdoor recreation for both solitude lovers and noisy companies. When planning all the features of the lifestyle and design of existing buildings on the garden plot, as well as having thought over every detail of the structure, you can quickly erect the building yourself. In order for the gazebo to turn out reliable and last for many years, it is necessary to use high-quality building materials and special protective impregnations.