At first glance, a staircase leading to a veranda or terrace may seem an insignificant detail, which is done according to the residual principle. In fact, this is far from the case. First of all, the steps of entering the house should be convenient and practical so as not to trip over them daily. Of course, the aesthetic component should be taken into account: after all, the entrance to the living room is a facade group, to some extent, the “face” of the entire building. And the first impression of the most beautiful and practical house can be spoiled by an illiterate designed ladder leading to the dwelling.

The choice of materials for construction

The staircase (entrance to the veranda) is located in the open air and is subject to various climatic influences (rain, snow, sun). Accordingly, if you want this construction to last long enough, you should take its construction seriously.

Most often, such materials are used for the manufacture of stairs:

- Wood. The advantage of this material is the simplicity of working with it; no purchase of any special tools is required. Most people with at least the slightest carpentry skills can work with wood. And the design of the stairs is quite simple, it is enough to have minimal construction experience and follow the instructions exactly. In addition, wooden structures look great, and if they are made from high-quality raw materials, they will last for more than a dozen years. But for this, oak, beech or larch need to be treated with protective compounds from pests and the effects of aggressive environments.

- Metal. An excellent solution for the manufacture of staircases, however, it has several significant drawbacks. It is not easy to work with metal, you need skills in using a welding machine, with a bending machine, etc. If you do not have such experience, you will have to contact a specialist, which entails financial costs, and metal cannot be called a budget option in terms of price. If you are familiar with plumbing, and the money issue does not scare you, metal is exactly what you need. A staircase made from it will last longer than the structure itself. And subject to regular surface treatment from corrosion, it will look great. Although more often this material is used for the manufacture of frames and individual elements, and the steps and railings are made of wood.

- Concrete. Universal material, despite its simplicity and unpretentiousness in terms of status, this is an excellent solution from a practical point of view. Concrete can be combined with any other material, and the structure itself can be given any arbitrary shape that your imagination can handle. Of the shortcomings, it should be said only about the need to fill the foundation, and for a rather long time until it completely dries out (at least four weeks).

- Brick. Excellent material, having some common qualities with concrete (ease of installation, versatility), but devoid of many of its shortcomings: there is no need to make iron reinforcement, the correct shape of the brick allows you to build almost any desired structure, etc. However, a foundation for such a structure requires capital, as for concrete structures.

Design requirements

Despite the fact that structures made of various materials have their own specific features, they all have some common features and must meet certain requirements, regardless of what they are made of.

Among these points, the following should be highlighted:

- for concrete and brick structures, it is necessary to make a monolithic foundation;

- for the safety of the stairs, it is advisable to equip the fence with a railing;

- step height - 17–20 cm, width - 30–34 cm. Such dimensions are dictated by the anatomical features of the average person. These parameters allow most people to go down and climb the steps in a natural step, "on the machine." If the height or width is changed to a greater or lesser side, the step will stray;

- if space allows, the angle of the stairs should not exceed 45 °;

- the minimum width of the stairs, sufficient for comfortable movement, is 90 cm;

- it is desirable that the number of steps be odd.

Did you know? Veranda - an open or glazed annex to the building is a type of terrace. These architectural structures have long been familiar to man - the first and perhaps the most famous such building was the famous gardens of Babylon.

Step Options for the Veranda

First you need to decide what type of stairs you will build. It is necessary to clearly understand what exactly you want to see, what type of structure you will create. The choice of design is extremely important, since it will be very difficult to remake something during construction. In addition, the cost of the work depends on what type of step you will be installing.

Among the whole variety of stairs, the designs of such varieties can be distinguished:

- Spiral staircase. This type of structure has a lot of advantages (requires little space, looks great). It is an excellent option for the installation of steps designed for lifting to the second floor. But there is a significant drawback - it is very difficult to correctly calculate all the details of such a structure without specific knowledge. It is necessary to take into account the height of the floor, the available area, the slope of the stairs, the width of the steps and the mass of other factors.

- Marching stairs on several slopes. The design is quite simple in calculations, easy and quick to install. In addition, the principle of construction of wooden and metal structures are similar, only the structural features of the fasteners differ.

- Corner staircase with one or more turns. It is used in buildings with a high basement, with a basement on the ground floor, for lifting to the second floor. Strength of the structure is provided by intermediate platforms that are attached to the walls of the building from the street.

- Brick and concrete steps of any shape (oval, semicircular, etc.). This is not to say that such structures are too complicated to manufacture, but require some skill and patience in the construction. But these efforts are more than justified by the versatility and durability of the stairs. In addition, you can make a threshold of almost any shape.

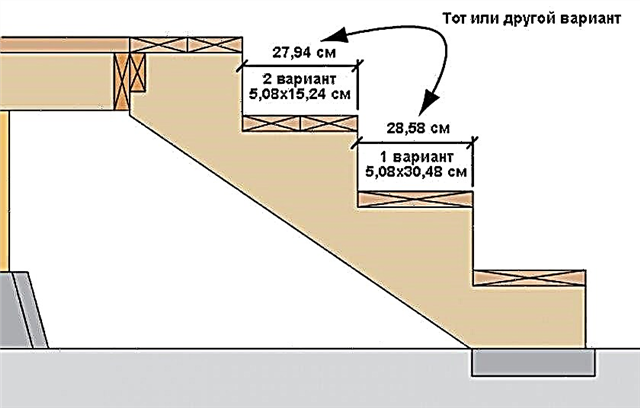

After you decide on the type of design, you should think about how the steps will be attached.

There are three common methods of attachment:

Project development

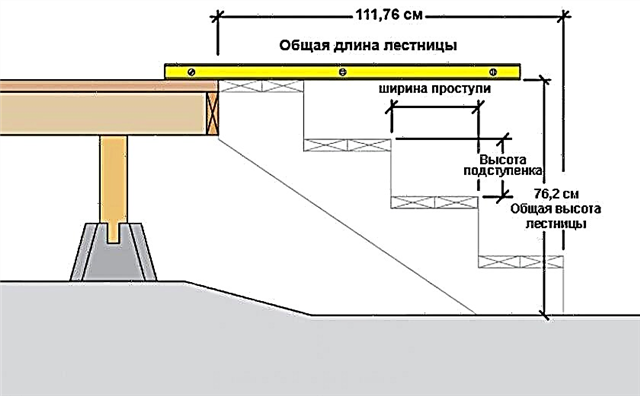

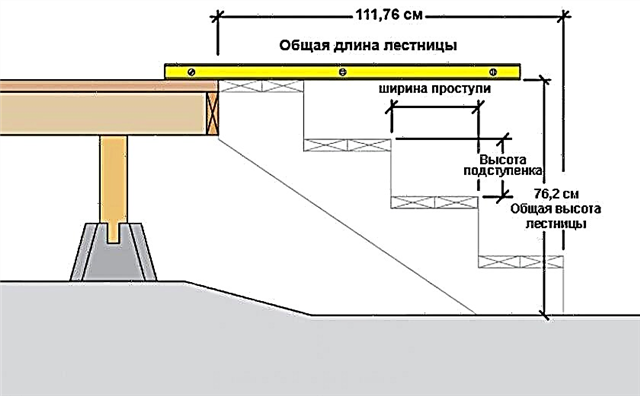

The next stage is the development of a detailed project and its embodiment in the drawing. In order that you do not have any undesirable nuances during the construction, you will need a drawing in any case. This is necessary so that you can check the construction project at any time and, if necessary, make changes. First of all, it is necessary to calculate the length of the stairs, the height and width of the steps.

Do this as follows:

- Using a level, draw a horizontal line at the top of the stairs. The total length of the structure should be indicated along the edge of the first step.

- Divide the total length by 28 (the width of one footboard) - you will get the number of steps. Fractions are rounded in accordance with the rules of mathematics.

- Using a plumb line, determine the overall height of the structure. This number should be divided by the average height of one step - 18 cm. For example, if the height of the edge of the floor of the veranda is 86 cm, then 86/18 = 4.77. Rounding this figure, get the number of stair elements - 5 pieces.

- The next step is to calculate the exact height of the steps. To do this, 86 cm (total height of the stairs) must be divided by the number of steps - 5, get 17.2. This will be the height of each element.

- Now you need to calculate the width of the steps. To do this, divide the total length of the stairs by the number of steps. For example, the distance from the floor of the veranda to the edge of the lower step is 1.24 cm. Dividing 124 by 5, you get 24.8 cm - the width of one tread.

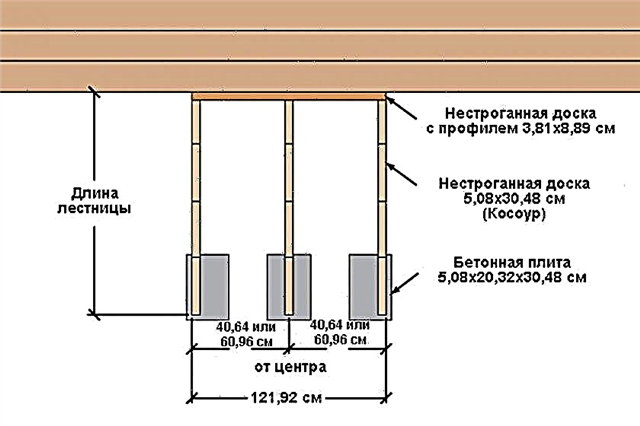

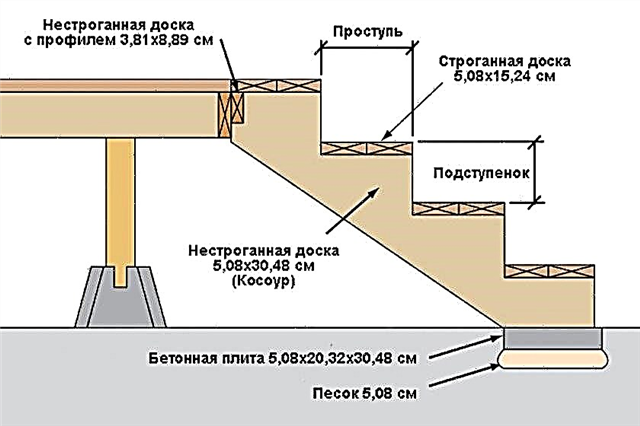

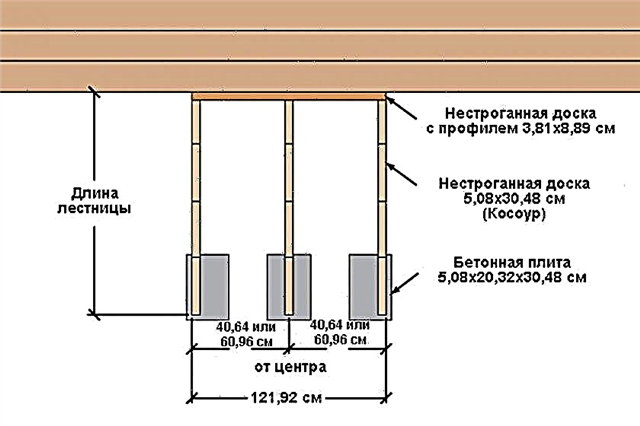

- Next, you need to determine the number of kosour. The distance between two braids should not exceed 40–45 cm. That is, for a staircase with a width of 90 cm, 3 elements must be made, for steps with a width of 1.2–1.3 m, 4 parts are required.

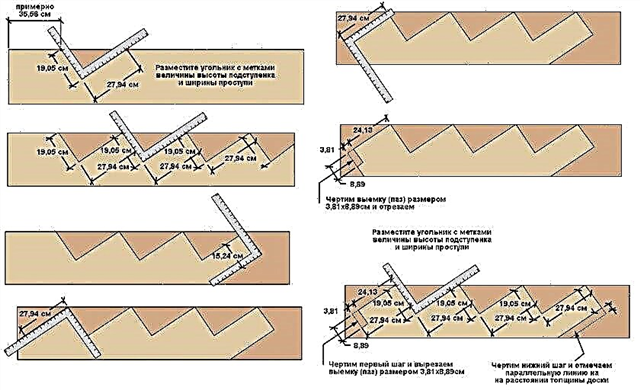

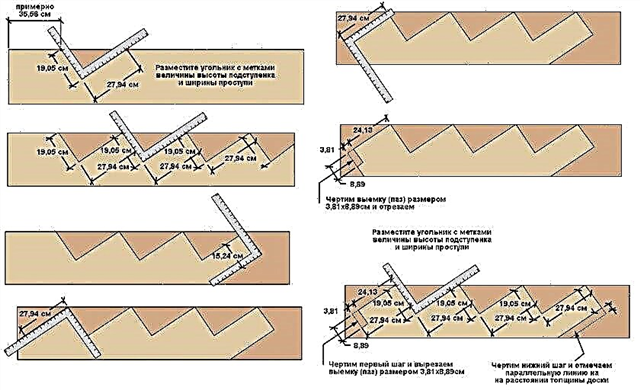

- Now you need to mark the cutouts under the steps on the Kosoura. To do this, you need a bench square. Marking is quite simple: mark the height on one side of the square, and the width of the tread on the other.

- The first at a future kosoura should indicate the height of the step. To do this, 34–36 cm should be retreated from the edge of the board, and draw a right angle from this point, one side of which is the height of the element, the second is the width.

- Draw the next ledge from the point bordering the first, and so on - all 5 steps.

DIY turn-based construction

Below are described in detail the main stages of manufacturing stairs from various materials.

Foundation under the stairs

In principle, it is not necessary to make a foundation for a wooden structure, although it is better to pay attention to this element. Wood will not be so prone to spoilage and decay, resting on a pillow of crushed stone or concrete. In addition, the presence of the foundation will not allow the structure to settle over time.

Important! Regardless of what type of structure you decide to build, regularly, at each stage, check the horizontal and vertical using the level and plumb.

For a wooden staircase, it is enough to dig a hole 30–35 cm deep, cover it with sand (10–15 cm), and gravel or gravel on top, and ram the pillow. Then you can pour it with cement, but you can leave it in this form, it will completely cope with its task. For the construction of concrete or brick structures, it is necessary to prepare a monolithic reinforced foundation.

Algorithm of actions:

- Dig a hole 8-10 cm wider and longer than the base of the stairs. Depth - 35–40 cm. From the boards or OSB-sheet, make the formwork, install it in the recess. It is good to first spill the wooden elements with water so that they swell and the gaps between the boards become smaller.

- Cover the bottom of the pit with roofing material. Connect reinforcing cage from reinforcement and iron wire, place it inside. Prepare a concrete mortar brand M-250. It is made of cement, sand, gravel and water (2: 4: 7: 1).

- Fill the foundation pit with concrete, lay the reinforcing mesh on top, leave to dry completely.

Wooden staircase

In order to make a staircase from wood, you will need such tools and materials:

- boards (25 × 250 mm);

- protective impregnation;

- hand saw or jigsaw;

- hacksaw;

- chisel;

- metal corner;

- hammer;

- screwdriver;

- nails

- self-tapping screws;

- square;

- level;

- plumb line;

- pencil.

Important! It is allowed in the process of pouring the foundation to fix corners on it - for lower fixation of the stairs. But there is no urgent need for this: the design will still hold normally, and additional fastening will only complicate the installation task, since it will be necessary to adjust the elements with greater accuracy.

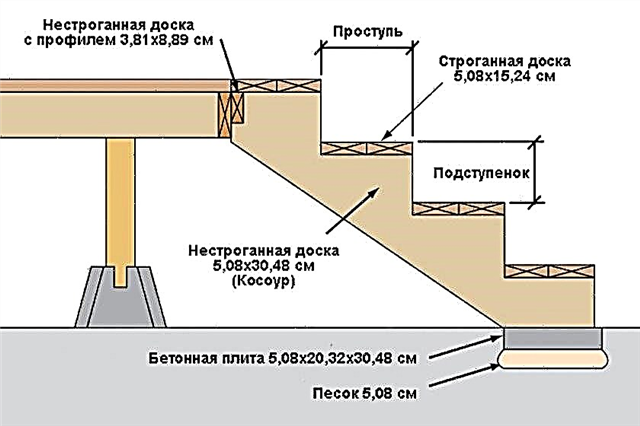

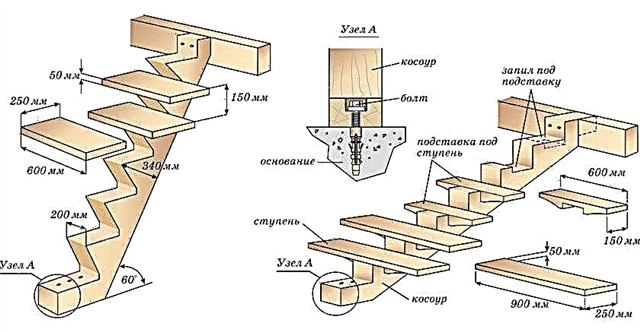

The procedure for the construction of a wooden staircase is as follows:

- At the selected site, make all necessary measurements (the height of the stairs, the distance from the lower step to the edge of the veranda floor, etc.), draw up a project and prepare a drawing.

- At the base of the stairs pour a foundation of sand, gravel and cement. Reinforcing such a foundation is not necessary.

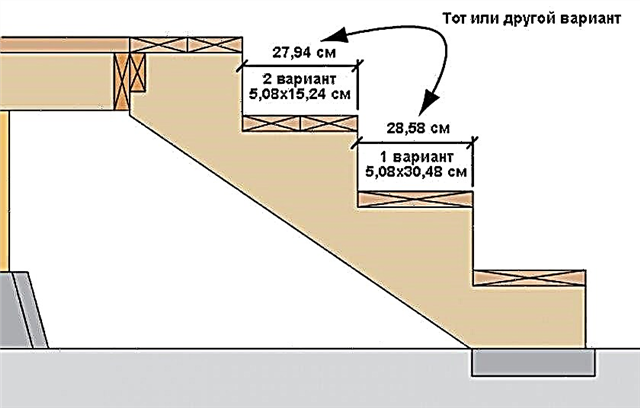

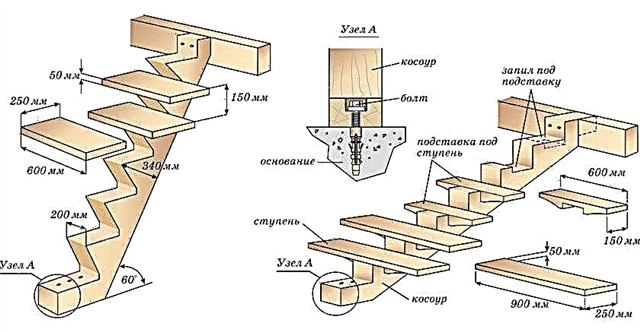

- If the width of the structure is 1 meter, it is necessary to make 3 kosour. In order for all the kosour to be the same, you should make a piece of plywood, on which all the elements of the staircase are cut. In order for the patterns, and later the skewers, to turn out smooth, it is necessary to use a joiner's square.

- Using a square, taking into account all measurements, mark the boards (25 × 250 mm) under the braid and cut out the corresponding parts. Elements can be cut with a hand saw or a hacksaw.

- Next, cut the steps and risers. Process all elements with a grinder.

- When all the parts are polished, you can begin to assemble and install the structure.

- First, the upper edges of the kosour should be fastened to the board, which will be attached directly to the veranda. This is best done with the help of corners and screws.

- The lower edges of the kosour are also interconnected using metal corners and a board that will lie on a concrete pad.

- After the kosour are installed, steps (treads) and risers are mounted on them.

- Steps can be made in such a way that the tread is flush with the riser, or slightly protrudes above it. In the treads make holes for the past. The railing itself, in addition to relying on the past, is attached to the veranda on the one hand, and to the lower step on the other. Fix pollen with metal or wooden studs.

Before installation, all wooden elements must be covered with wood-protective impregnation, such as “Tikkurila Eko Wood”, “Luxens”, “Pinotex Ultra”. Then your design will last a long time.

Before installation, all wooden elements must be covered with wood-protective impregnation, such as “Tikkurila Eko Wood”, “Luxens”, “Pinotex Ultra”. Then your design will last a long time.

Iron staircase

In order to make a metal structure, you will need:

- metal profile 40 × 20 mm;

- welding machine and electrodes;

- board 25 × 250 mm;

- timber 30 × 50 mm;

- bolts, nuts and washers;

- spanners;

- metal corners;

- enamel for external metal work.

The basic principles of building a metal structure are in many ways the same as for a wooden staircase. The difference lies in the fact that the frame and skewers are cut from a metal profile or corner.

The overall progress of the work is as follows:

- First you need to build a foundation. For such a structure, it will be enough to dig a hole of the appropriate size and a depth of 30–35 cm. Lay a layer of sand (10–15 cm) on the bottom, crushed stone from the top to the edge of the recess. Tamp the foundation well and pour it with a cement mortar.

- Metal parts must be connected using a welding machine. In this way, skewers and transverse elements are made, which connect them into a single frame.

- From the metal profile create the elements of the railing, the past is welded on the sides of the stairs, at the top - a metal corner or channel under the railing. All metal parts must be brushed and painted with enamel for outdoor use (PF-115, Tikkurila Panssarimaali, ALPINA DIREKT AUF ROST, etc.)

- When the frame is mounted, its upper edge should be screwed to the edge of the veranda with bolts and nuts. Then the metal base must be sheathed with wooden treads. Whether you should set up risers is up to you, but you can do without them.

- Lay wooden railings on metal rails, cover them with impregnation and varnish.

Concrete pouring structure

To make the stairs in the above way, you will need such tools and materials:

- cement;

- sand;

- crushed stone;

- water;

- formwork boards;

- fittings and metal wire;

- reinforcing mesh;

- metal profile for railing 40 × 20 cm;

- plumb line and level;

- wooden beam 30 × 50 mm;

- buckets;

- concrete mixer (if any);

- rule and trowel for concrete;

- facing tile.

Did you know? Currently, for the construction of verandas and terraces they use thermowood - a specially treated wood (up to indicators above the burning temperature of the material). At the same time, the molecular structure of wood changes, and it becomes immune to temperature extremes, precipitation, bright sunlight and other aggressive environmental factors.

A concrete staircase is a great step option for the veranda. The main thing is to make the formwork correctly.

The order of work is as follows:

- First you need to fill in the monolithic reinforced foundation, on which the porch will subsequently be built. How to do this was described in detail above.

- Cut formwork elements from boards or OSB boards: two side elements and risers.

- Install the finished formwork in the place where the steps will be built. All wooden elements on the outside should be strengthened with supports, otherwise the formwork may fall apart under the weight of concrete.

- Place the reinforcing cage inside the formwork. It must be made of pieces of reinforcement interconnected by a metal wire.

- It is possible to weld a structure consisting of a square frame (it will be installed directly on the foundation) and 4 vertical posts (two low and two high) from a metal profile. This will be the past, on which you need to weld the railing guides.

- For pouring steps, concrete of the M-250 brand is suitable. How to do it was described in detail above.

- Concrete building should be periodically watered with water (if it is hot in the street), on the tread lay a reinforcing mesh.

Depending on weather conditions, it will take up to four weeks for the stairs to completely dry. The finished structure can be covered with tiles, and wooden rails can be strengthened on metal rails.

Video: DIY concrete steps

Made of bricks

In order to make a staircase from brick, you will need such materials:

- brick;

- cement;

- sand;

- water;

- buckets;

- trowel for working with bricks;

- hammer;

- level and plumb;

- metal profile 40 × 20 cm;

- facing tile;

- timber 30 × 50 mm;

- varnish to cover wooden railings;

- enamel for painting metal parts.

You can build a brick staircase in this way:

- According to a previously prepared drawing, lay out the structural elements: first the side elements and the lower stage.

- In the niche formed between the step and the sidewalls, pour rubble, it is good to ram it.

- On the cushion of rubble, build the second stage so that the bricks partially overlap the first stage. To fill the resulting niche with rubble and so - to the very top.

- Each horizontal and vertical surface is monitored by level and plumb.

- On both sides of the lower and upper steps, between the bricks, put pieces of reinforcement so that they protrude 3-4 cm outwards. To them, after the entire structure has dried, the wood will be welded on which the railing needs to be installed.

- The finished structure can be tiled, but the brick itself looks good, so you can leave the stairs in this form.

You can make a staircase to the veranda from a variety of materials. Each of them has its own advantages and disadvantages. And although the specifics of working with wood, metal, brick or concrete is significantly different, the structures of these materials have a lot in common. The main thing is to know the basic principles of construction and strictly follow the drawing, observing certain rules.